About: Borgesius Rotterdam

Subject: Borgesius Rotterdam invests in ZELA2100 and tiger paste system: efficiency and quality go hand in hand

Source: NBT Magazine

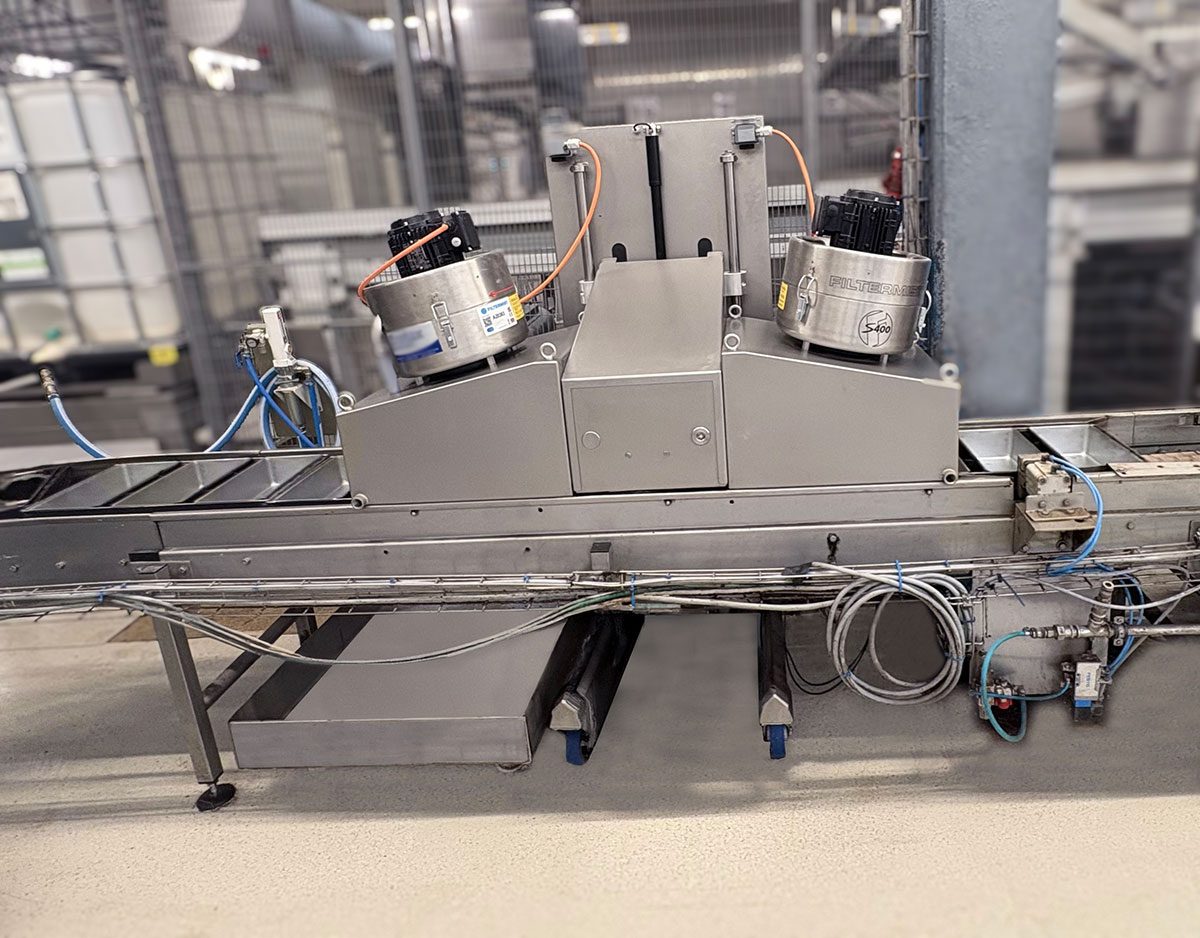

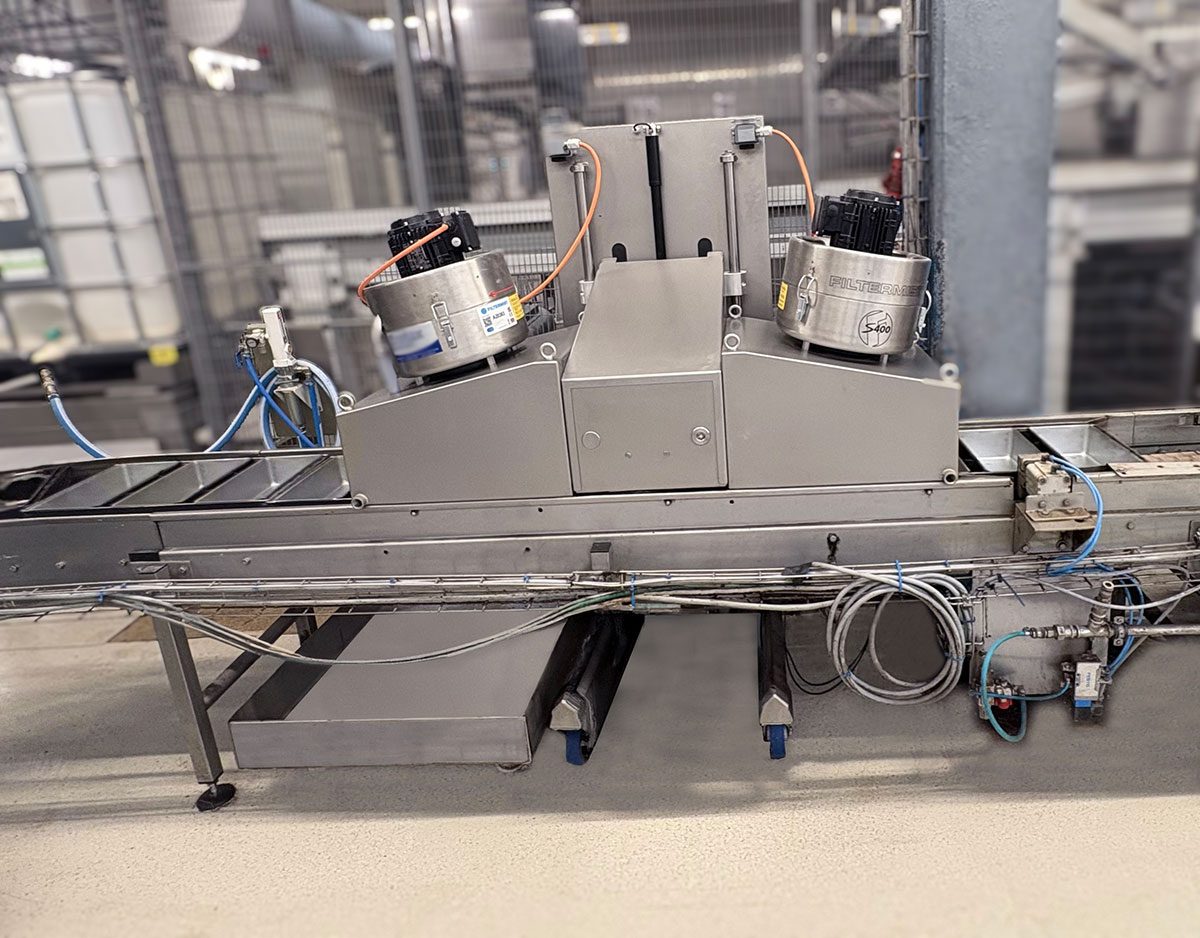

Automation has been a key theme in the bakery industry for years, but the latest generation of machines takes process optimization to the next level. Borgesius in Rotterdam is experiencing this as well, where two ZELA2100 greasing machines and a ZELA tiger paste system were recently installed. Both machines were developed by Zela Technical Solutions, part of the EverBake Group, and are known for their ease of use, precision, and hygienic design.

The ZELA2100 fully automates the greasing of baking pans, with a consistent and efficient spray pattern that ensures perfect release and an even result. The ZELA tiger paste system ensures efficient and consistent preparation of tiger paste, preserving the artisanal character while significantly speeding up the process.

For the Borgesius bakery in Rotterdam, the investment not only represented a step forward in product quality and efficiency, but also a noticeable reduction in strenuous, repetitive work for the staff. We recently took a look behind the scenes of this project: from the selection of ZELA machines to the first practical experiences. “The reason was simple,” explains Hans van Scherpenzeel, bakery manager at Borgesius Rotterdam. “We have two large-scale bread lines, and the fifteen-year-old tin-lubricating machines were due for replacement. There were times when we had to spray by hand. That’s when you realize: this is absolutely essential.”

The choice for ZELA was an obvious one. “We already had good experiences with their baking tins and trays, and our contact with EverBake was excellent. We also recently purchased the Tiger paste system for several Borgesius locations. That made the decision for EverBake a much easier one, especially because of the positive feedback. The ZELA2100 is adjustable above the tray, has excellent extraction filters, and ensures less contamination. It’s a real pleasure to work with. We estimate we spray half a gram less per pan, which equates to about 200 liters per week. We still need to monitor this further in practice, but it’s promising.”

Quality and reliability

For Borgesius, reliability was a decisive factor. “With the volumes we’re producing, you can’t afford extended downtime. You absolutely have to be helped quickly if something happens. ZELA is an established name, and we know that EverBake offers excellent service. If there’s a problem, you get help the same day, which is unfortunately no longer a given in the Netherlands these days.”

Tiger paste system

The tiger paste system was previously pilot-tested at the Leeuwarden facility. “We saw excellent results there. It’s a modern machine, incorporating the latest technology. The preparation vessel is attached to the machine, ensuring consistent quality, regardless of the operator. We porridge after the final proofing, preventing the porridge from dripping off the dough and ensuring optimal results. Moreover, the quantity is easy to adjust—always precisely 45 grams—and the porridge lies flat, without any stoppers in the line.”

Efficient process, high volumes

The tiger paste system at Borgesius processes around 270,000 loaves of bread every week, with peaks of up to 330,000. “From tiger whole wheat and corn to white and brown – we have a huge variety. Demand for tiger bread has grown rapidly in recent years. Thanks to the agitator in the storage tank, the porridge always remains homogeneous and ready to use, even if the machine is idle for a while. This makes the process much more flexible.”

Installation without major interventions

According to Scherpenzeel, the installation went smoothly. “The most important thing was maintaining a constant flow on the sheet metal conveyor. The new machines could be installed in exactly the same location as the old ones, with only minor adjustments. This way, the process remained largely unchanged.”

Prospect

The first few months have shown that the investment is paying off in several ways: higher and more consistent product quality and less waste. Scherpenzeel concludes: “With the volumes we produce, you simply have to have a reliable machine. That was the main reason we chose ZELA.”

Technical highlights ZELA2100 greasing machine

• Fully adjustable spray unit for width and height

• Multiple nozzles for a consistent and economical spray pattern

• Equipped with exhaust filters for a clean working environment

• Easy to clean thanks to its movable design

• Reduces grease spillage by an estimated 200 liters per week

Technical highlights ZELA tiger paste system

• Integrated mixing tank with agitator for consistent homogeneity

• Precise dosing (at Borgesius, 45 grams per loaf)

• Continuous process without line stops for the application of the paste

• Suitable for high production volumes of up to 330,000 loaves per week

• Movable on casters and equipped with a dedicated cleaning program

Question or quote?

Curious what we can do for you? Complete the quotation form and we will contact you as soon as possible.